In April I went to Copenhagen and like any urbanist/normal person/american it had me walking (and biking) around feeling hopeful and frustrated at the same time, reiterating “WE COULD HAVE SO MANY NICE THINGS.” Things, in this context being accessible public spaces, cities built for people, bike lanes, creative and cool dense housing, etc. But the “nice thing” from my visit that I’d like to tell you about today is an inspiring solution to our textile waste crisis.

I went to the Design Museum Denmark and was thrilled to find one of their exhibits “Fabric of Change” centered on upcycling.

The exhibit centers around Upcy, an off-shoot of the Danish laundry company Textilia. Textilia provides uniforms for chefs, linens for hospitals and commercial spaces, and other textile goods, mostly in the hospitality space. The company made a commitment to be fully circular (meaning all of their products that are discarded are re-used) by 2025, and Upcy was created to help towards that goal by re-sewing the discarded products into new goods, which also provides a new business opportunity for the parent company.

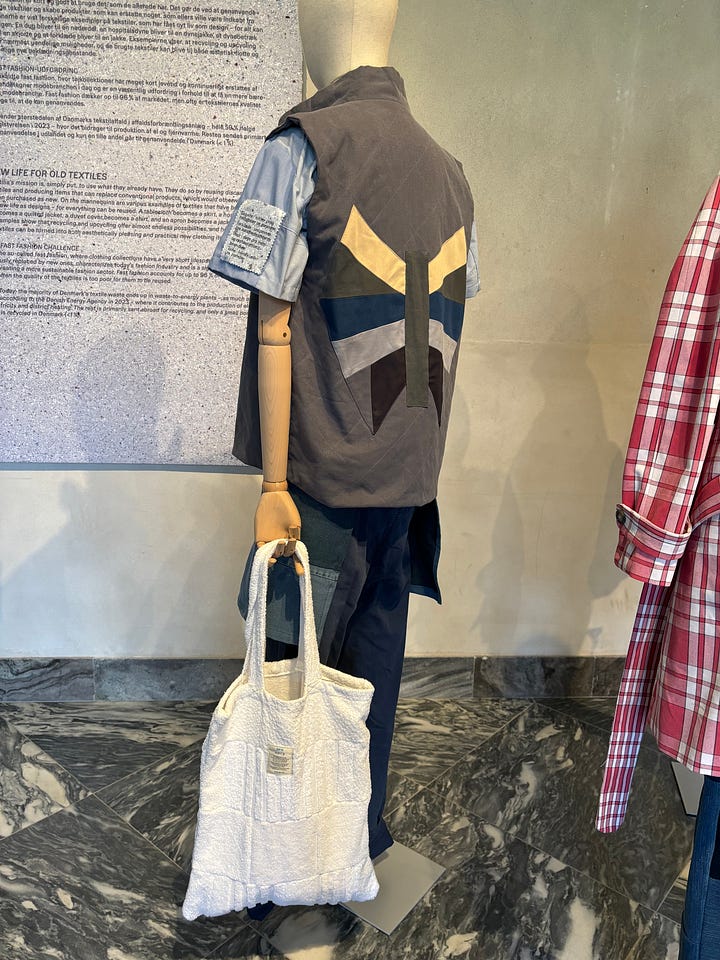

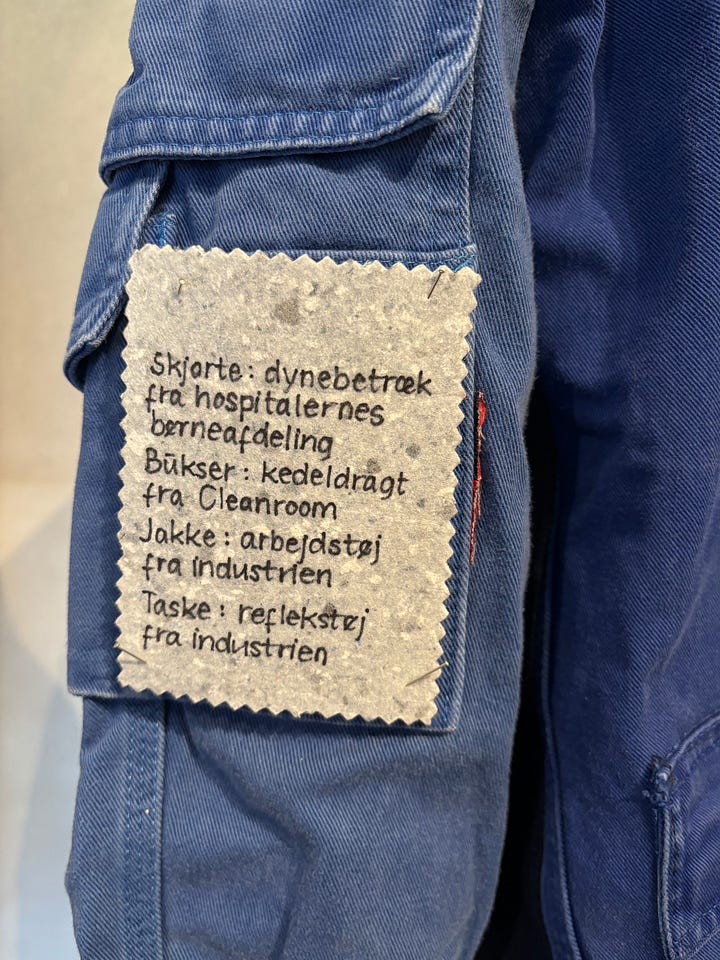

What this exhibit (and the brand in general) does is show tangible examples of upcycling with post-consumer textiles and explain how the company prioritizes different types of re-use. There were 8 mannequins dressed head to toe in upcycled looks, with a fabric badge pinned to the garments saying what they used to be.

On the exhibit wall they had a good summary of how they prioritize re-use before upcycling.

PRIORITIES FOR RECYCLING AND REUSE

FIRST PRIORITY: EXTEND LIFESPAN: repair and maintenance of textiles

SECOND PRIORITY: REUSE : Reuse is better than recycling

THIRD PRIORITY: RESEWING: Re-sewing used textiles is better than breaking them down. As C02 emissions are relatively low, energy is only used for transport and the sewing machines

FORTH PRIORITY: FIBER RECYCLING: Breaking down used textiles is a less favorable solution than resewing but better than producing new textiles. The C02 emissions from mechanical breakdown, yarn production, and weaving new fabric are energy intensive processes. Recycled textile fibers will always represent a downgrade from the original raw materials.

It was encouraging to see an example of resewing at a relatively large scale. It paints a vision of creative solutions to our waste crisis, and asks us why the industry doesn’t look like this more broadly?

The answers you might hear for why are wide-ranging and complex, but I think it boils down to something quite simple: it’s a solution that is very labor intensive, and therefore very capital intensive. Small apparel brands trying to do everything right are struggling to stay afloat, and big brands with significant capital aren’t interested in real solutions, they are only interested in brushing up their image to not look like the bad guy.

We’ve seen various voluntary take back programs by US and European brands, but aside from a couple they haven’t developed into anything of substance. As Daphne writes in Why One H&M Skirt Traveled 15,000 Miles After It Was Brought Back to the Store,

“We found that more than three-quarters of these clothes—in great condition, in perfect conditions, fit to be reused—were either destroyed, stuck in the system, or sent to countries that are already struggling to deal with the amount of clothing that comes from Europe.”

When we think about the rest of these big companies' business models, it is unsurprising that their take back programs have failed to deliver on their promises. Like a lot of problems, we can’t rely on the goodwill of companies to do the right thing (although I do think social pressure on businesses is a good thing), we need regulation. As I was thinking about this, I started looking into the current status of Extended Producer Responsibility (EPR) legislation for textiles around the world. Here is a great explainer on EPR, but in short it is a policy lever that holds brands responsible for the collection, sorting, and recirculation of their products when discarded by citizens. This can be done by enforcing the brands themselves to own this process, or by enforcing a fee towards local authorities’ waste collection work. You can nerd out and read the whole 72 page report by the Ellen McArthur foundation with suggestions for EPR policy, but I’ll relay to you here what I found to be the most interesting.

The report talked about how if an EPR policy were to base a fee structure around the amount of new products that a company was placing on the market, it could help

“Incentivize producers to adopt circular business models — such as resale, rental, and repair — while moving away from linear business models. In addition, applying lower fees to second-hand products (compared to new products) can further encourage the uptake of reuse models. As demonstrated by the French EPR scheme, a proportion of EPR revenues can be mobilised to financially support repair operations.”

Now this is a vision I can get behind! It uses the principle “polluters pay” to enforce that those who produce the most new products, and therefore the most waste, should be held financially responsible for the mess they have made. It answers the hard questions of how we could make repair and upcycling a financially viable business model, and levels the playing field for brands trying to operate in a more circular manner.

The other important thing I’d like to point out from the report is that the current state of EPR around the world is incomplete because “producer responsibility stops at the point of export.” This means that while local/national EPR policies fund the collection and sorting of textiles in their country, they make no demands on/provide no funding for handling of the waste if it is transferred to another country. The OR foundation does a great job outlining how this is a social justice issue, and I think it’s imperative that policy makers keep in mind funding the entire waste management chain when drafting any EPR legislation.

I wrote most of this piece a while back, and as I sit trying to finish it on July 5th, it does feel a bit trivial as Congress just passed the Republican budget bill with steep cuts to Medicaid and clean energy, and a huge new budget for ICE to terrorize our communities. I mean, why publish a piece calling for EPR when we have a lot more important fish to fry? But I want to push back against this instinct and remind myself that it’s important to ideate on solutions that we may not currently have the power to implement. Beyond that, I also think that it’s important to work towards solutions to our waste crisis even without adequate support and funding to do so. While it is important and necessary to require companies that created our textile waste crisis to clean it up, it is an admirable and creative task to work towards solving this crisis prior to legal change, and Textilia is a great example of one company doing just that.

I’ve got another piece in my drafts about my favorite brands and individuals doing upcycling with post-consumer waste, but I would love for you to drop yours in the comments!

I enjoyed this sm! A ‘simple’ shift from a linear to circular thinking with economic issues actually has such a big impact on that way we consider everything, especially resources and profit. I also think solution-based thinking is so important rn when everything feels very doomsday. Thanks for showing something that highlights a way through 💡

Wow! I love all of this. Thanks for reporting on and writing this— even amidst all the awful that is happening in the US. Creating while reusing previous materials makes me so happy— and gives me energy and motivation to work on other issues ( like trying to keep our country from going to a full-on police state). Good work!